U-Boot VIIC (Revell RC conversion)

U-Boot VIIC (Revell RC conversion)

- Length: 93,3 cm

- Weight: 3,2 kg

- Scale: 1:72

- Type: static diver, liquid gas ballast system.

RC conversion of the 1:72 U-boot VIIC made by Revell. Partially based on Norberts Bruggen WTC Kit, however with my own liquid gas ballast system.

Built Start: 20.07.2006

Built finish: 03.08.2008

Maiden Voyage: 15.08.2008

Built

Everyone who looks at the Revell’s VIIC 1:72 box immediately thinks that the model is huge. And it is, but only if we look at it in the terms of plastic models. However, if we treat it as a hull for the RC model with a static diving system, the situation changes drastically. There’s very little space there. On the internet I found some information/plans and attempts to develop an RC version of the model and I based my built on two particular projects. I did try to consolidate the best features from both as none seemed perfect for me.

I got the idea of the diving system from the RCsubs.net run by Ota Gerza, however Ota uses (used as it’s not in production any more) the CO2 canisters in his WTCs, while I wanted something safer – with lower pressure – like the liquid gas used in the early Davids Meriman WTC kits. The aft “mechanical” section was based on Norberts Brugen kit.

Both systems were quite expensive : 300 i 530 Euro (price tags from the year 2007). It was way to much for my student pockets back then. I had to make my own, getting some of the parts from the cheaper one.

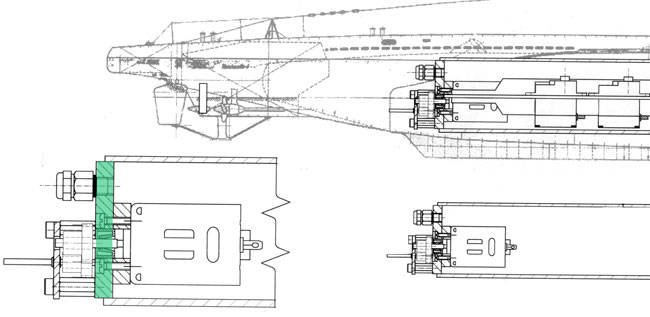

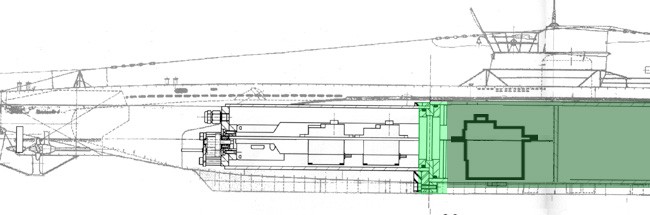

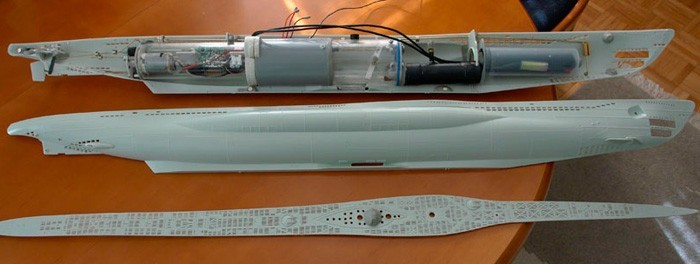

You can divide the model into 4 sections:

– red: (first from the left) battery compartment.

– violet: ballast tank and the gas tank.

– green: space for the receiver and the high torque servo for the dive tank.

– blue: connector between the 50 and 60mm pipe.

– green: main motor and rudder/diving planes servos.

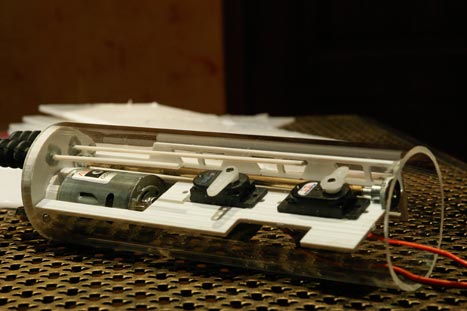

“Engine room” – aft section of the boat.

The aft section of the model is always the most difficult and the most crucial element of the model. It’s the equivalent of the engine room in the real vessels. Here you’ll find the propulsion system, shafts seals and the pushrod seals. In the case of Revells VIIC, the difficulty raises cause of the small amount of space and the fact that VIIC has a two dual drive. The aft section of this model houses two micro servos, electric motor: class 400 (12V) and a two-way speed controller. All this in a tube with a diameter of 50mm and a length of 150mm. There’s really very little space.

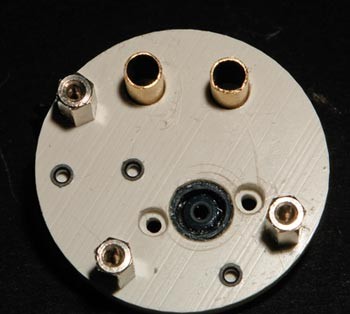

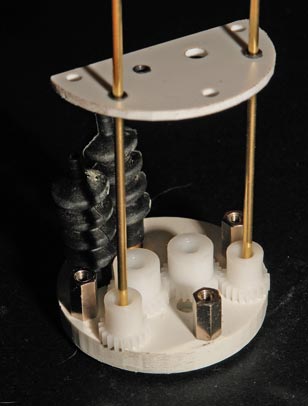

Photo on the right: You can see the aft bulkhead of the model. The shafts gasket, two brass tubes for the pushrods seals and the metal “bearings” for the external gearbox.

Photo on the left:

Photo on the left:

You can now notice the seals – two rubber bellows for the pushrods and the two 2mm shafts – however not connected to their gears yet. The plastic gears are made by Conrad , they’re optimized to run wet, at least that’s what manufacturer states on his website.

Further modifications and development.

The final assembly of the engine room with running in the motor and it’s gearbox.

My thought at this time was that with a longer transparent tube you could just make a second tray for the batteries with the receiver and you would have a finished WTC for a dynamic diver.

Section for the receiver and the servo operating the ballast system:

The section housing the RX and the power servo for the ballast tank has been marked with the dark green color. The light green is the special element which connects the 50mm tube with the 60mm one.

On the right: The CNC machined elements before and after assembly.

On the right: The CNC machined elements before and after assembly.

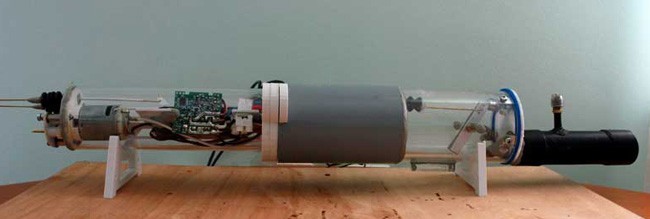

Servo tray with the 60mm bulkhead, which separates the dry section from the ballast tank. Of course not glued in yet.

On the right you can see the grey ABS tube housing the servo and the receiver and the transparent tube serving as the ballast tank.

Final assembly of my middle section.

Final assembly of my middle section.

Inside the grey tube you can see the high torque servo – almost hidden completely. It’s right behind the white connector which keeps the 50mm tube with the 60mm in place.

Ballast tank and the liquid gas tank:

The gas tank has been made from a cooper pipe with a diameter of 28mm with two caps on it’s ends. The gas inlet is the same as we can find in the refillable lighters, while it’s outlet was made from a modified schrader valve (car tire valve).

I did try using the 12 gram CO2 cartridges at first, but firstly I had terrible problems controlling its pressure and secondly I couldn’t get a decent efficiency. Quickly I turned towards the liquid, non flammable gasses. The cooper tank allowed of storing about 5 litters of uncompressed gas and that meant emptying my 250mml ballast tank for about 20 times. The gas which I used was tetrafluoroethane.

Above you can see my first self made liquid gas ballast system. The lever is connected with a high torque servo. When it swings to one side it floods the tank. When it swings to other it presses the schrader valve which releases some gas and empties the tank.

A fully operational WTC:

The first tests:

My first made WTC didn’t look very impressive, it was very poorly balanced but it worked! It was also completely dry inside after spending 2 hours under water.

Hull and the deck:

Cutting the flooding and venting holes took me some time but that’s okay. I enjoy those kind of works I guess. It was my first time when I had to work with so many of them and to try make them identical. It took me almost a week to get the job done, but I had to learn the technique. The first half of the hull took me almost 4 days, while the second one only 2 days. Experience is the power!

Everything was cut off manually, then filed down for a smooth surface and fine shaped with sanding paper. Then the time came fur cutting out the little holes in the deck. In the internet you can buy the brass deck kits for the VIIC, but… Firstly, I had no money for it, secondly: brass deck elements could block the radio signal and thirdly: extra weight above the water line is something really worth avoiding.

Flooding/venting openings have been cut out along the entire side line, at the bottom of the stern and in the bow section of the model too. As I mentioned earlier, I have cut out all the holes in the main deck too. I wanted to make sure that there will be no trapped air under the deck, but that was a mistake as I didn’t took the surface tension of the water into account and it the end the main deck required some bigger holes and few other modifications to enable the boat to be properly trimmed.

Flooding/venting openings have been cut out along the entire side line, at the bottom of the stern and in the bow section of the model too. As I mentioned earlier, I have cut out all the holes in the main deck too. I wanted to make sure that there will be no trapped air under the deck, but that was a mistake as I didn’t took the surface tension of the water into account and it the end the main deck required some bigger holes and few other modifications to enable the boat to be properly trimmed.

Final assembly and tests.

The whole idea was that, when you want to charge the batteries, you remove the main deck and take out only the small watertight cylinder housing the battery pack. The valve for replenishing the liquid gas is also easily accessible from above. If you need to access the main WTC – for example repairs or occasional maintenance, then you need to disconnect the pushrods, propeller shafts and then you can dissemble hull apart and take out the WTC.

The whole idea was that, when you want to charge the batteries, you remove the main deck and take out only the small watertight cylinder housing the battery pack. The valve for replenishing the liquid gas is also easily accessible from above. If you need to access the main WTC – for example repairs or occasional maintenance, then you need to disconnect the pushrods, propeller shafts and then you can dissemble hull apart and take out the WTC.

Rudders and dive plane tests.

A short clip showing how the rudders and the dives planes work. Funny fact – the lever rotating the dive planes is 1mm thick. Yes… 1mm! Things like this are only possible with carbon fibre which was (and is) strong enough.

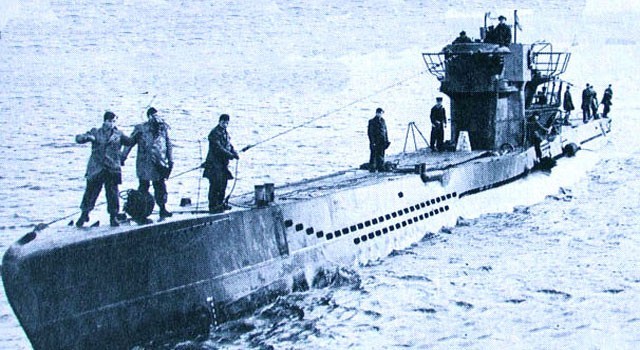

I did some small research about the real things and their waterline before trimming:

Final tests of the main drive, ballast tank and the general water tightness – all went quite well. Trimming the boat was a real problem (or maybe it was my lack of experience in the 2007) but I managed to achieved a “so so” trim. Sadly my ballast tank was to small to get a correct waterline.

Running the model:

To be honest I’m not fully happy how the model behaves nowadays (2017), but I was extremely happy and proud back then. In my opinion the rudders are way to small and the same goes with the diving planes. The turn radius is enormous and the diving is really hard. The model swings terribly from one side to the other and sits a little to deep in the water. Someday I’ll make a second version of its WTC for sure, together with bigger planes and rudders. The ballast system is still fun! It’s a nice view when it surfaces with all those bubbles around!

Last update: 03.07.2017

Using any of the materials gathered here without the written consent of the author is strictly prohibited.